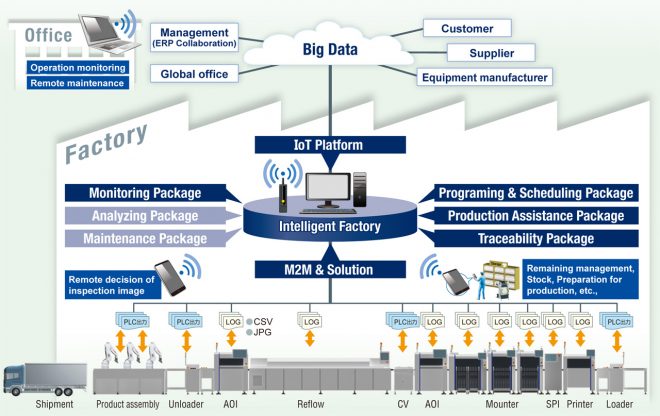

【YAMAHA】Intelligent Factory

IoT/M2M Integration system – System allows linking our SMT machines to equipment made by other companies and give all-around high productivity in the mounting process.

Programing & Scheduling Package

Production data Programming—Optimizing—Grouping

P-ToolFor Mounter, Printer, Inspector

Optimization

Generates streamlined PCB data to shorten production time. Common part allocator function for multiple products slashes man-hours needed for production setups!

Data Conversion (ASCII Data Conversion)

Converts data generated by CAD and other equipment into Yamaha data.

Grouping

Optimizes multiple boards by automated grouping, setup and changeovers into common, collective shape. Slashes man-hours needed for production setups to cut the overall production time.

Visual Editor

Shortens time for creating PCB data and boosts quality.

P-Tool EcoExclusive for Printer & Dispenser

P-Tool simplified version includes essential functions for printers and dispensers.

P-Tool AOIExclusive for Inspector

P-Tool simplified version includes essential inspection functions

Production Assistance Package

Remaining parts and setup error monitoring, part expiry monitoring, and rank monitoring

Setup Error Monitoring

Set-up Navigation (S-Tool)

Navigates through external setups onto carriage. Collates ID to prevent components setting task errors.

Note :Connecting the cart and PC sets environment equivalent to that on the machine (Consult us for details.)

Setup Verification (IT Option)

Requests part stock from PCB data. Navigates through the setup/changeover sequence. Collates ID to prevent task errors.

Note : Information scanning via two-dimensional code. (Consult us for details.)

Material Time Limit Management (S-Tool, IT Option)

Checks components stock information during setups and production while taking storage information such as for solder and MSD into account. Issues components stock ageing or deterioration warnings. Prevents use of components stock that reached its expiry date.

Rank Monitoring (S-Tool, IT Option)

Mounts LED parts by rank. Reduces data monitoring load such as for board data and prevents work errors by collating by rank.

Remaining Parts Error Monitoring

Remaining Components Monitor (M-Tool)

Monitors remaining part status from PC mounted alongside production line.

Parts Remain Counter (IT Option)

Monitors remaining number of components, and requests resupply before running out of components. This reduces machine downtime by preparing components beforehand.

Monitoring Package

Monitors productivity and product quality, etc. Note: Requires machine monitoring operator to monitor the target machine, dedicated PC, Tool Drive, M-Tool View during operation.

Floor Monitor (M-Tool View)

Checks the overall floor production status on the Web.

Line Monitor (M-Tool View)

Checks the line status (line efficiency, operating ratio, pickup rate, etc.) in real-time.

Traceability Package

Product lot tracing, process condition tracking, etc. Note: Requires T-Tool dedicated server PC and IT Option tracer output for target machine during operation.

Production history search (T-TOOL)

Searches production history data such as components lot information accumulated in the server, to swiftly and smoothly pinpoint the utilizable range and effective scope of components used in production.

Product Traceability (IT Option)

Outputs the machine information to T-Tool server.

Note : Capable of verifying 2-dimensional code on production PCB.(Consult us for details.)

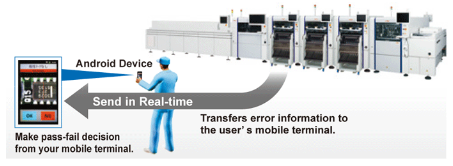

M2M & Solution

Links M2M (machine-to-machine) and links to other company’s equipment, line solutions, etc.

Auto Program Change-Over (IT Option)

Automatically selects conveyor width and PCB data for production line by scanning barcodes listed on the board and the instruction sheet.

QA Option

When an error occurs, this function pinpoints the head on the mounter placing components, and shows an actual video image of the pickup position and pickup state.

SPI linked functions

Ensures high positioning accuracy by linking SPI with our company printing functions and feeding back information on solder misses during printing.

Note: Please consult us for information on corresponding manufacturers and functions.

3A Process Control

A part mounting position corrector function ensures the terminal of each part is uniformly mounted on the printed solder by correcting the part mounting position.

IoT Platform

Platform linked to the internet and cloud environment

Platform connects our company equipment and machines in the factory to create a cloud environment.

Please consult us to obtain further information.