An in-vehicle device manufacturer was planning to introduce a new mounter and asked us to help them create a database of the components used. We created a work routine for efficiently inputting the mass data between their business activities. As the work for creating components data was simplified from the initial stage of introduction, the client was very happy to be able to start using the mounter promptly.

From SMT facilities to industrial robots

MASS is a trading company specializing

in electronics production technologies

Without electronic boards, planes can’t fly,

cars can’t run, PCs can’t start, and our streets and cities can’t function.

Electronic boards form the core of all electrical appliances in today’s electronic society.

MASS sells and provides maintenance services for such production facilities.

Together, we will strive to help our customers attain the next step,

and serve as the core of Monozukuri (manufacturing).

NEWS

PRODUCTS

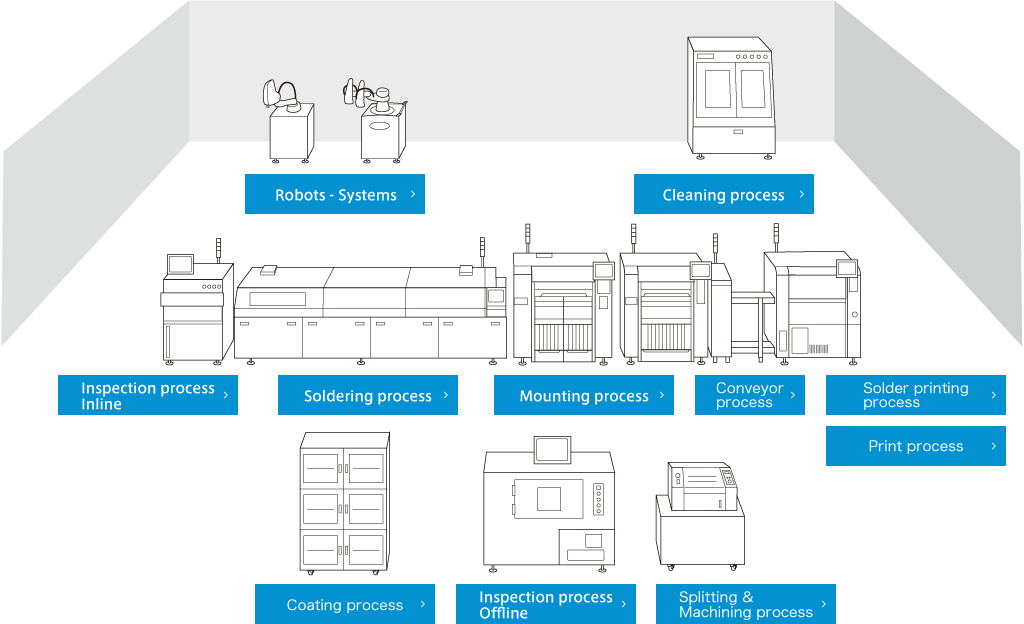

We offer a broad spectrum

of high-quality production equipment.

Mass Corporation can boast a full and diverse lineup for all types of production sites ranging

from SMT equipment for production systems to peripheral devices and industrial robots.

We offer the best possible equipment to meet the customer’s needs.

Product List

Mounting process

Mounting process

Coating process

Coating process

Solder printing process

Solder printing process

Soldering process

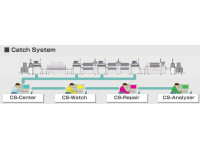

Inspection process

Cleaning process

Conveyor process

Conveyor process

Splitting & Machining process

Splitting & Machining process

Robotics

Others

Manufacturers

We also handle products and equipment from many other manufacturers.

SERVICE

-

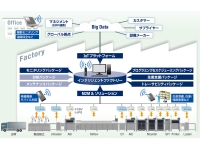

TOTAL SOLUTION

From production systems to peripheral equipment, MASS proposes optimal facilities for your needs.

-

ENGINEER

Having problems with your machine? Call MASS first.

-

GLOBAL NETWORK

Support system that always keeps close to customers who go overseas.

CASE STUDIES

-

- Trouble:

- We need to create mass components data when introducing new facilities.

- Solution:

- MASS helped to create a components database.

-

- Trouble:

- We want to build boards using a non-standard process…

- Solution:

- MASS proposed the optimal line by combining the facilities of several manufacturers.

A medical equipment manufacturer wanted to install a line which included a special process. They wanted to shorten the tact time and reduce the number of facilities used. Accordingly, we proposed the best production line for their needs which consisted of the equipment of several manufacturers. As the line differed from their normal process, we repeatedly checked that quality is maintained. The customer was able to achieve the quality they were looking for, limit the tact time to within their target, and is currently rolling the system out to their plants around the world.

-

- Trouble:

- We want to reduce the data creation time and misinformation rate.

- Solution:

- Cut the data creation time from 1.5H→0.5H and improved the percentage of defect-free products from 80% to 99.5%

An in-vehicle manufacturer was taking 1.5 hours to create the inspection data for one model. They wanted to reduce this data creation time and raise their percentage of defect-free products.

Through discussions with the manufacturer, they were able to reduce their data creation time to 0.5 hours by adding new functions. They also succeeded in reassessing their inspection data and conditions, and in raising the percentage of defect-free products from 80% to 99.5%. -

- Trouble:

- We want to enhance efficiency by dual lane operation.

- Solution:

- Improved the efficiency of their planned maximum production volume up to 120%.

An EMS manufacturer decided to install a dual lane system.

They were facing many problems as they were also using conveyors made overseas. Therefore, we arranged for engineers from the different manufacturers to grasp the present situation in the respective countries and resolve the issues thoroughly. As a result, the customer was able to improve the efficiency of their planned maximum production volume by 120%.

They complimented us with the remark, “We have never had a manufacturer or trading company that supported us to this extent.”

NEWS

- Latest Information

- Publication

- Product Exhibits

-

Cannot find contents

-

Cannot find contents

-

Cannot find contents