INFORMATION

ABOUT US

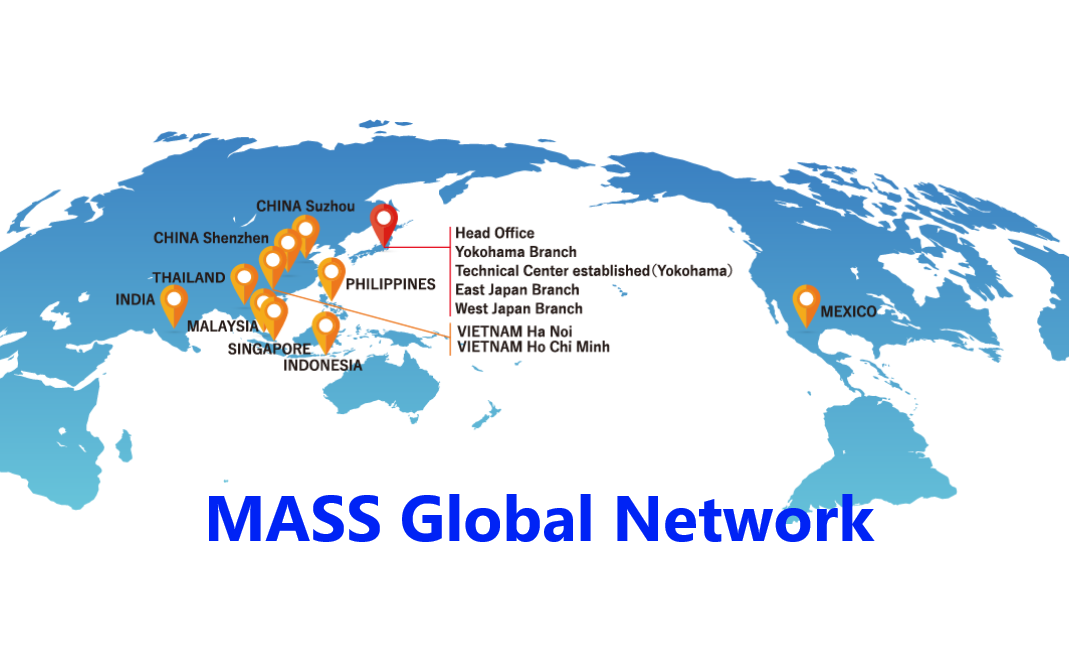

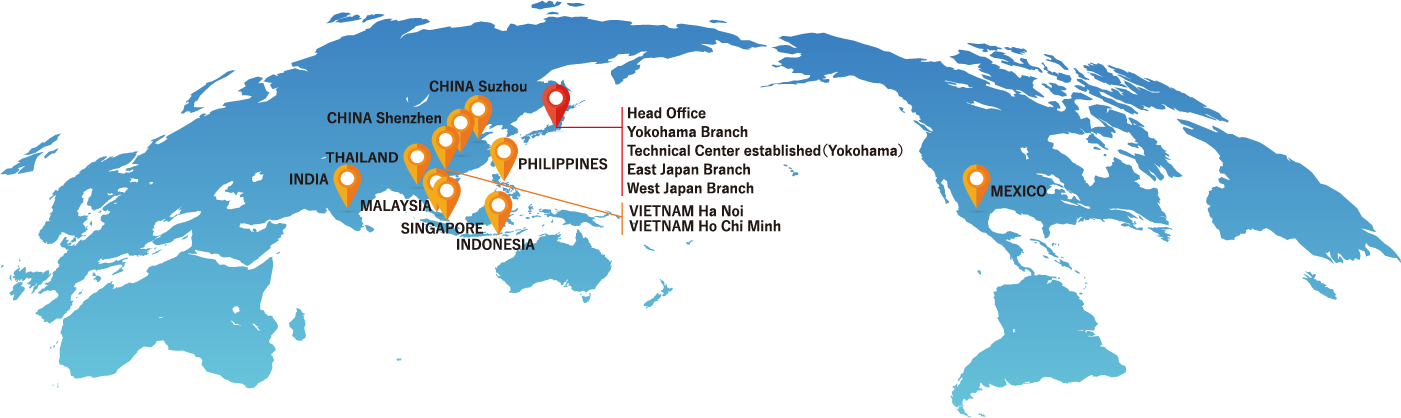

We provide total solutions that move the world using

our global network of 11 locations in 9 countries.

SERVICE

We manage manufacturers and suppliers and

propose optimal solutions to our customers.

Selection ability that meets advanced needs.

Through actual machine evaluation,

we will propose the model that best meets your needs.

Manufacturers

We also handle products and equipment from many other manufacturers.