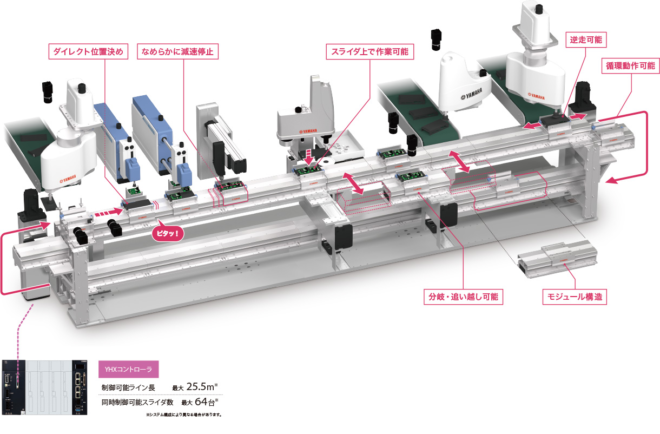

リニア搬送のパイオニアYAMAHAが提案する、

次世代工場の搬送プラットフォーム

特徴

一瞬たりともムダにしない生産工程の実現

- 停止精度:±5μm

- 最高速度※:2,500mm/sec

※搬送質量が10kgを超える場合は、質量に応じて1,000mm/secまで下がります。 - スライダ間ピッチ:210mm

基本仕様

| 駆動方式 | ムービングマグネット式コア付リニアモータ | |

|---|---|---|

| 位置検出 | 磁気式アブソリュート位置センサ | |

| 最大可搬質量 | 30kg | |

| 最高速度 | 2,500mm/sec ※1 | |

| 繰り返し位置決め精度 | ±5μm | |

| ロボットスライダ間機差 | ±30μm (ノック穴基準) | |

| 最大連結ストローク | 25.5m ※2 | |

| 最大ロボットスライダ数 | 64台 ※2 | |

| ロボットスライダ間最小ピッチ | 210mm ※3 | |

| 本体外形 | 本体断面最大外形 | W175×H109mm(ロボットスライダ込み) |

| リニアモジュール長 | 200/300/500/1000 | |

| ロボットスライダ長 | 198mm | |

| 本体質量 | リニアモジュール | 約20kg(リニアモジュール1mあたり) |

| ロボットスライダ | 2.4kg | |

| 電源 | 制御電源 | DC48V 所要電力[W] = 75[W/m] × モジュール全長[m] ※4 |

| モータ電源 | DC48V 当社指定機種※5 | |

| 使用環境 | 使用温度 | 0℃~40℃ ※6 |

| 保存温度 | -10℃~65℃ | |

| 使用湿度 | 35%~85%RH (結露なきこと) | |

| コントローラ | YHXコントローラ | |

※1:搬送質量が10kgを超える場合は、質量に応じて1,000mm/secまで下がります。※2:システム構成により異なる場合があります。※3:ロボットスライダに搭載する治具パレットの方が長い場合は、治具パレット長+10mmとなります。※4:オプションの1000W電源で最大13.3mのリニアモジュールに供給可能です。※5:オプションの1000W電源で2台までのロボットスライダに供給可能です。※6:LCMR200の運転は、設置・調整を実施した環境温度±5℃で行ってください。※7:YHXコントローラ用に別途電源が必要です。

スタンダードプロファイル仕様

| 使用可能コントローラ | YHX-HCU | |

|---|---|---|

| 運転方法 | ポイントトレースポイント番号指定位置決め、直値指定直接座標指定位置決め | |

| 対応ロボット | LCMR200、LCM-X、GXシリーズ (LCMR200とLCM-Xを混在させて制御することはできません) | |

| インターフェース | YHX-PP、フィールドネットワーク通信 | |

| 動作種類 | 絶対位置移動 | |

| 登録可能な最大ポイント数 | 65535 | |

| 制御軸数 (スライダと単軸ロボットの合計、 ただし、単軸ロボットは最大で16軸まで) | EtherCAT | 64 |

| EtherNet/IP™ | 64 | |

| PROFINET | 64 | |

| CC-Link | 22 | |

| 主な入出力 その他の機能は取説をご確認ください。 | 全軸対象入力 | サーボオン/オフ切替/インターロック/アラームリセット |

| 全軸対象出力 | サーボ状態/インターロック状態/アラーム状態/ハートビート/非常停止状態 | |

| 個別軸対象入力 | サーボオン/オフ切替/原点復帰/制御範囲内での位置決め移動(LCMの乗継動作含む)/制御範囲外からのスライダ挿入準備/制御範囲外へのスライダ排出/ジョグ移動・インチング移動/移動停止 | |

| 個別軸対象出力 | サーボ状態/原点復帰状態/各種実行状態表示用専用出力 指定ポイント番号/現在位置/軸アラーム状態 | |

| 主なリモートコマンド その他のリモートコマンドは取説をご参照ください。 | 設定データの書き込み、読み出し | |

| アラーム確認 | ||

| 積算走行距離、乗継回数の書き込み、読み出し | ||