AZVisionはここが違う

- 移動軸なし 1ショット最速3秒の高速タクト

- ワンボタンだけのシンプル操作

- マルチショットで表→裏の順次検査可能

- バーコードでワンタッチ機種切り換え

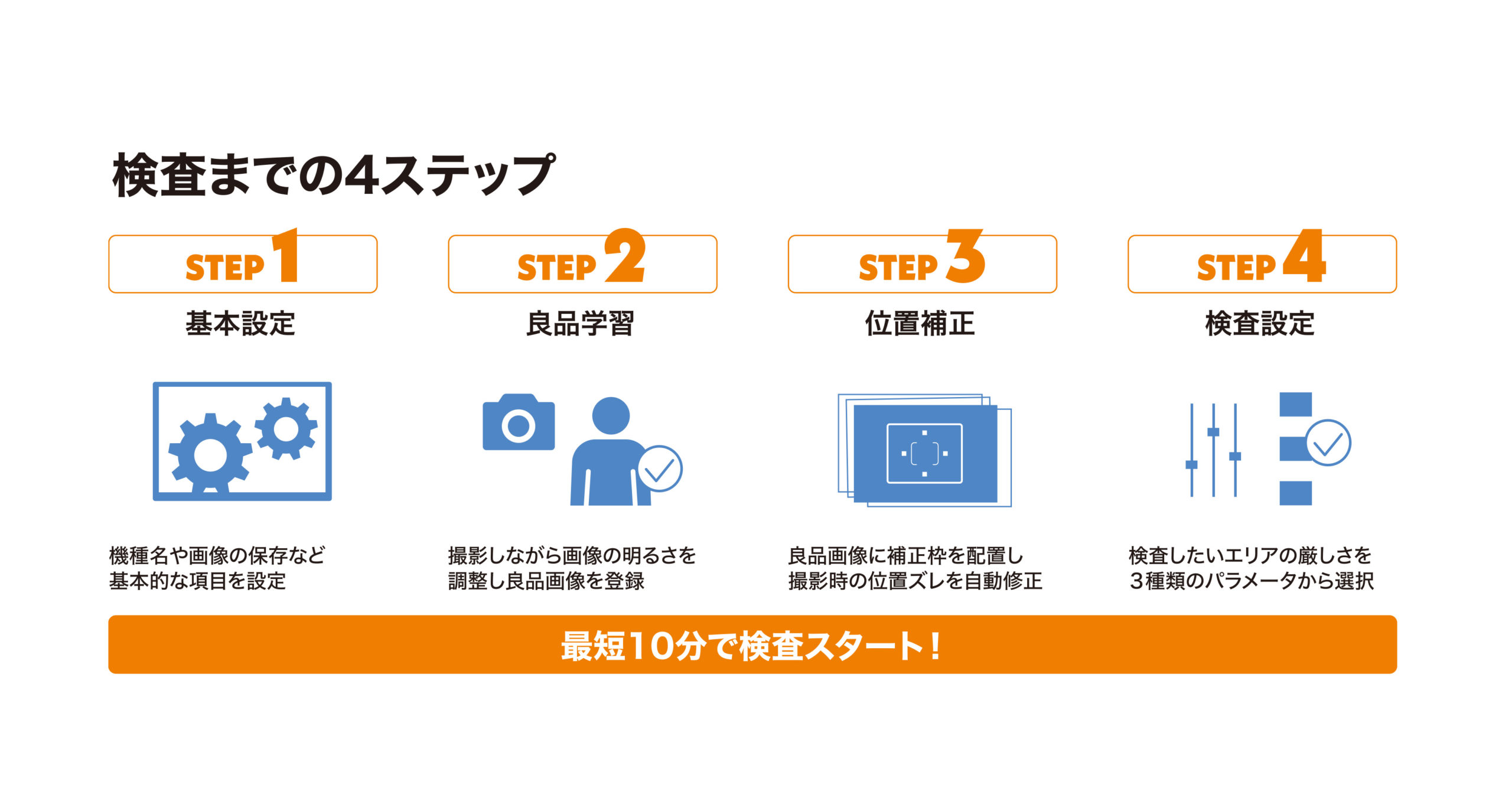

- 基本設定10分で検査開始

- サーバーなど任意の場所へ画像保存

- ロット完成数、作業タクトを計測

- 基板印字QR/DM読み取りでトレサビも万全

特許取得の「メッシュマッチング技術」で広い画像の見たい部分だけを精細に検査

部品単位ではなく、画像全体を均一に分割した「メッシュ」単位で検査。ざっくり全体を見たい時も、細かい部分に拘りたい時も柔軟に設定可能です。個々のメッシュが上下左右に最近似部分をサーチするので、わずかなズレで虚報が出ることはありません。形だけではなく、色や輝度の違いも検出、さまざまな検査用途に適合します。

色サーチ機能を新搭載 位置精度のない部品を追従して判別

従来のメッシュマッチングでは対応の難しい、位置精度のない部品の検査が可能となりました。足の長い差し部品の欠品の他、シリコンや手押しの刻印など、これまでの自動検査が難しかった様々な対象の検査が可能になりました。

スマートHDR機能

暗い部分はそのままで、白い部品の「白飛び」を自動補正。コネクタの切り欠きによる方向判定や金属面の文字の判別などに役立ちます。

広角レンズ+画処理でピント合わせ不要 高さ80mmの部品まで検査可能

従来の画像検査装置の常識を覆し、短焦点の広角レンズを採用。歪曲収差補正技術との組み合わせで、周辺まで歪みのない画像のまま、すべての部品にフォーカスが合っており、検査に支障はありません。カメラの高さ調整も不要となり、タクトタイムの短縮化を実現しています。

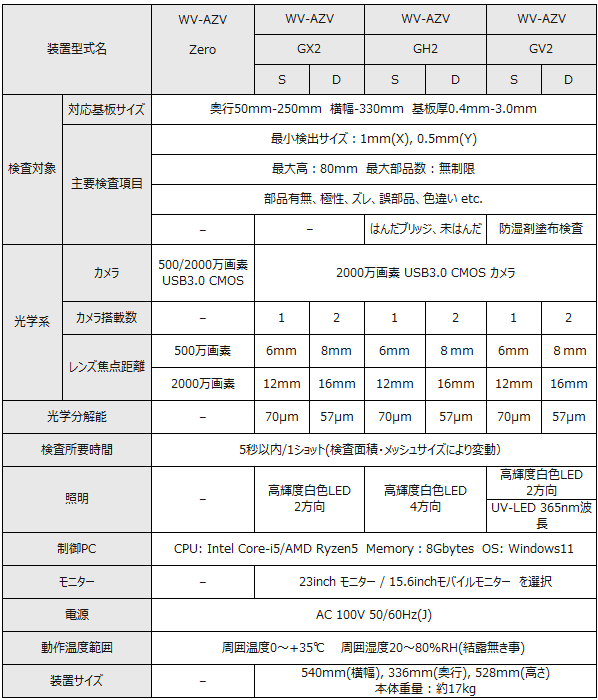

ラインナップ

Zero

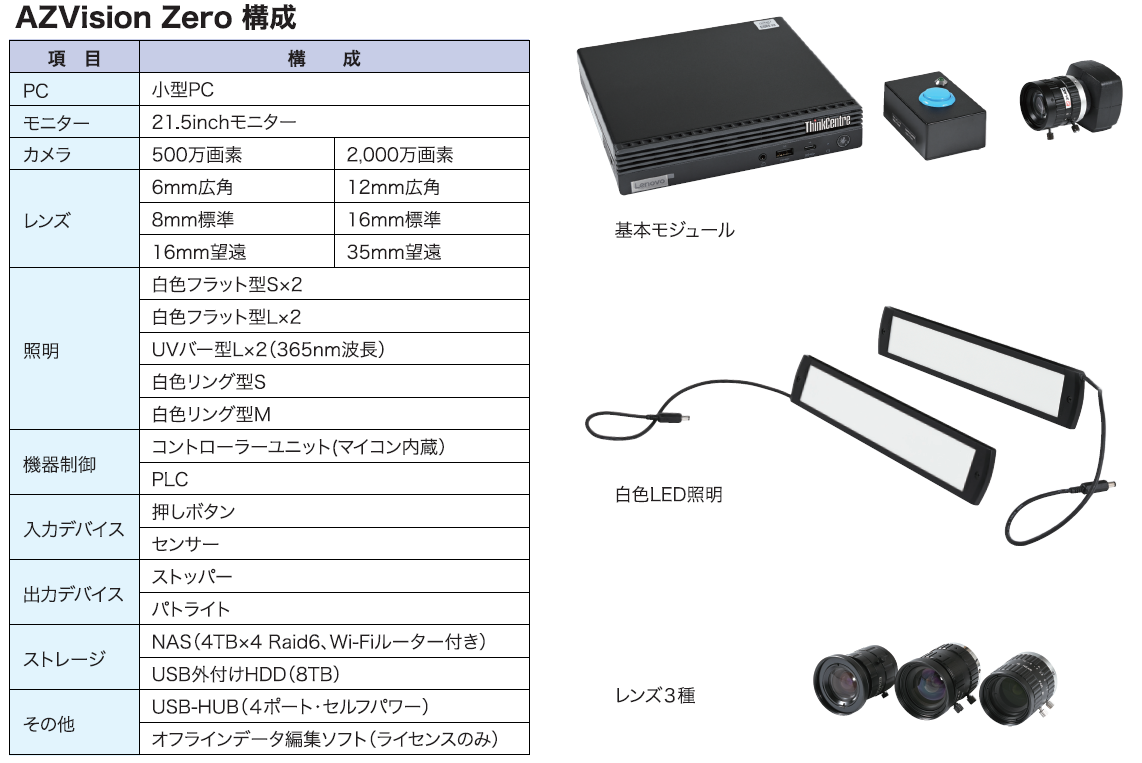

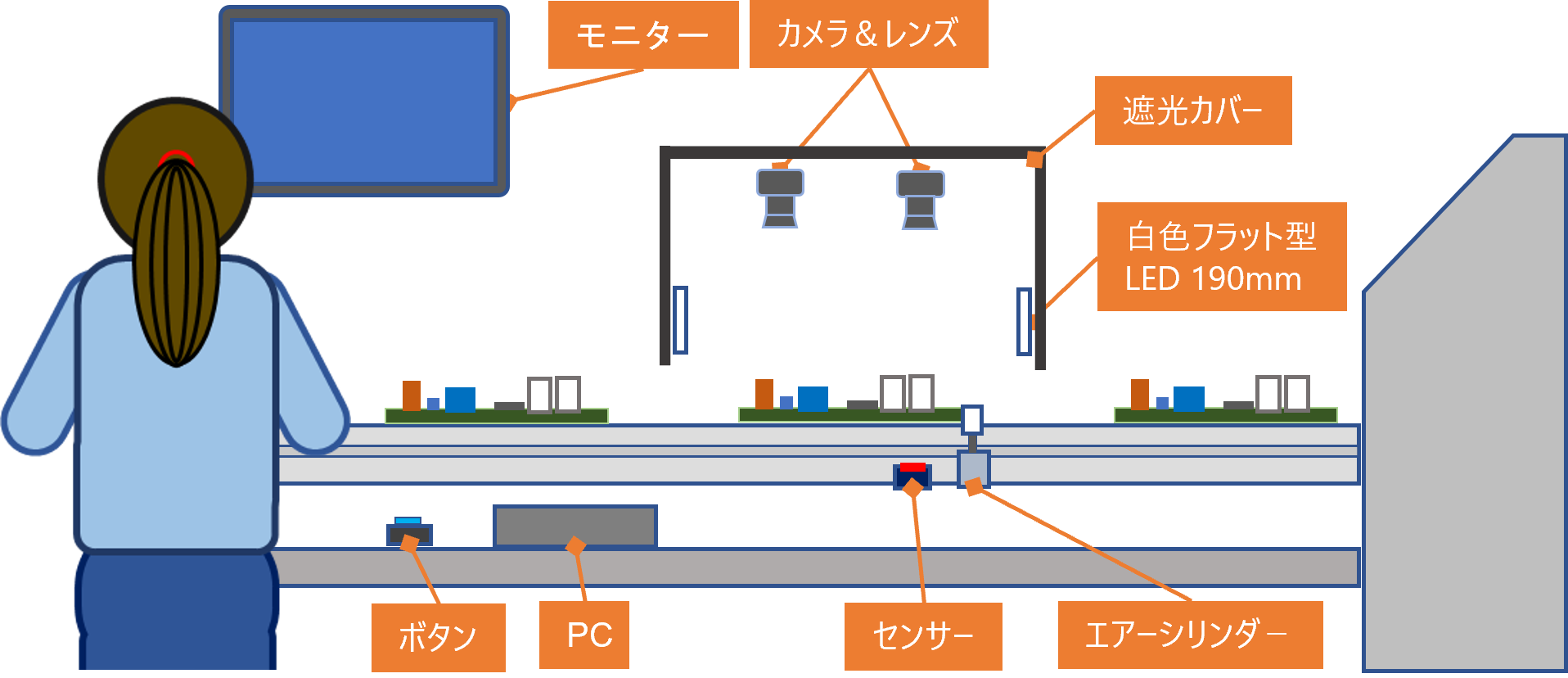

インライン化やロボット連携など組み合わせ自在なカスタムベース

カメラ・PC・ボタンボックスを基本モジュールとし、レンズや照明など多彩なオプションの組み合わせが可能。標準装備のI/Oではんだ槽前の中間コンベアへの設置やXYロボットとの協調など、活用方法は無限大です。

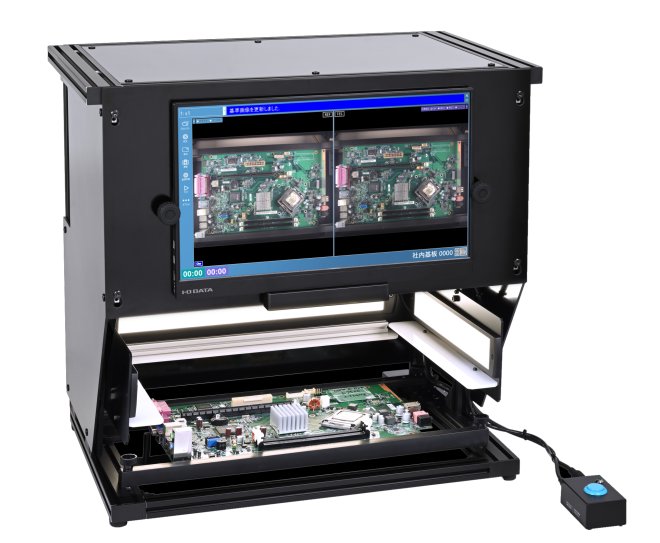

用途別に最適化したワンパッケージモデル

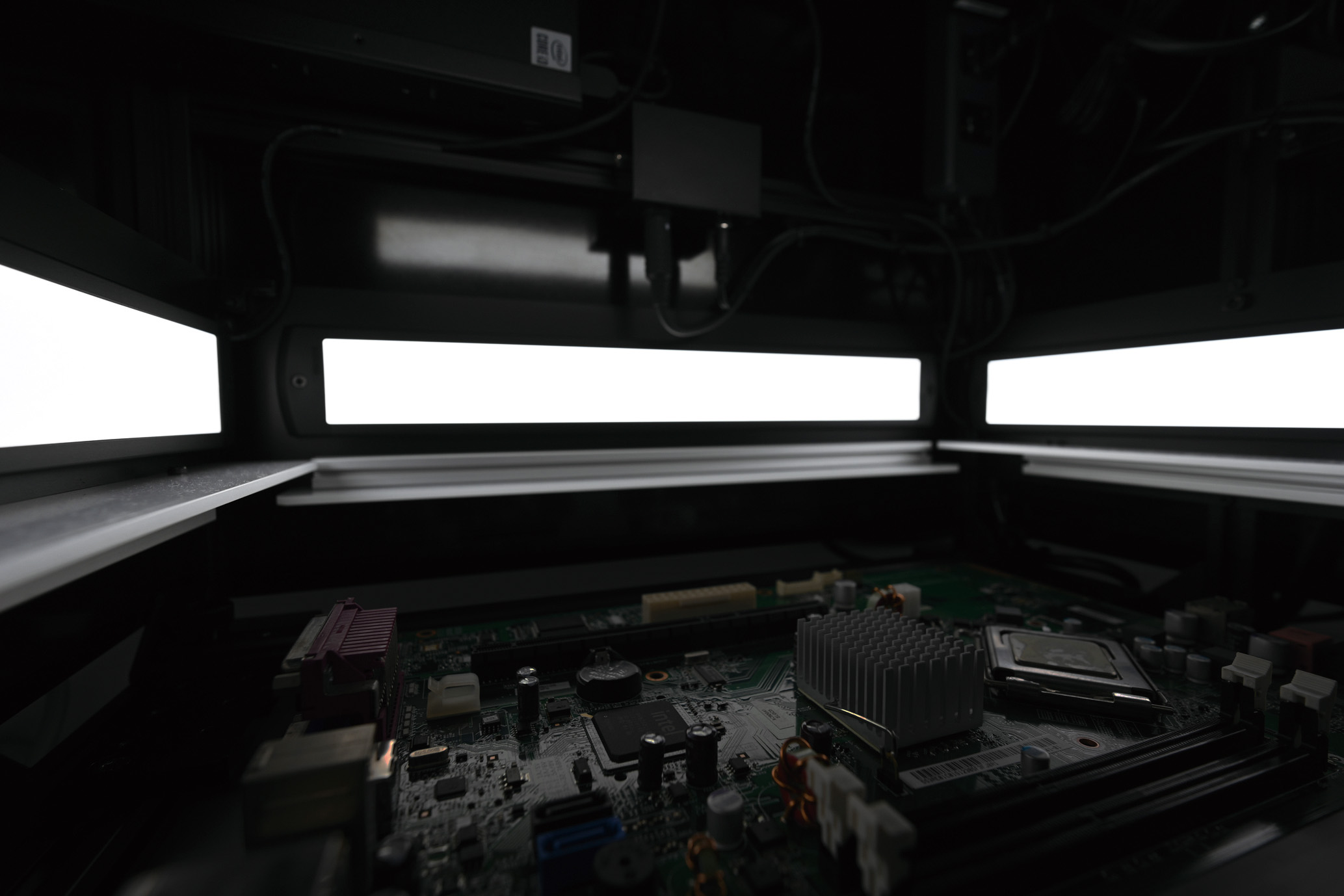

■100V電源ケーブル1本のシンプル配線

■PC+モニタービルトイン(※1)で進化したパッケージング

■2,000万画素カメラ 1基/2基の選択が可能で更なる高精細化

■全機種前面カバー装備で外乱の影響をカット

■横幅540mmのコンパクトな筐体でMサイズ基板をサポート(※2)

※1 21.5inchモニター選択時を除く

※2 両面検査やコンベア内蔵のインライン機、L基板対応機も製作承ります

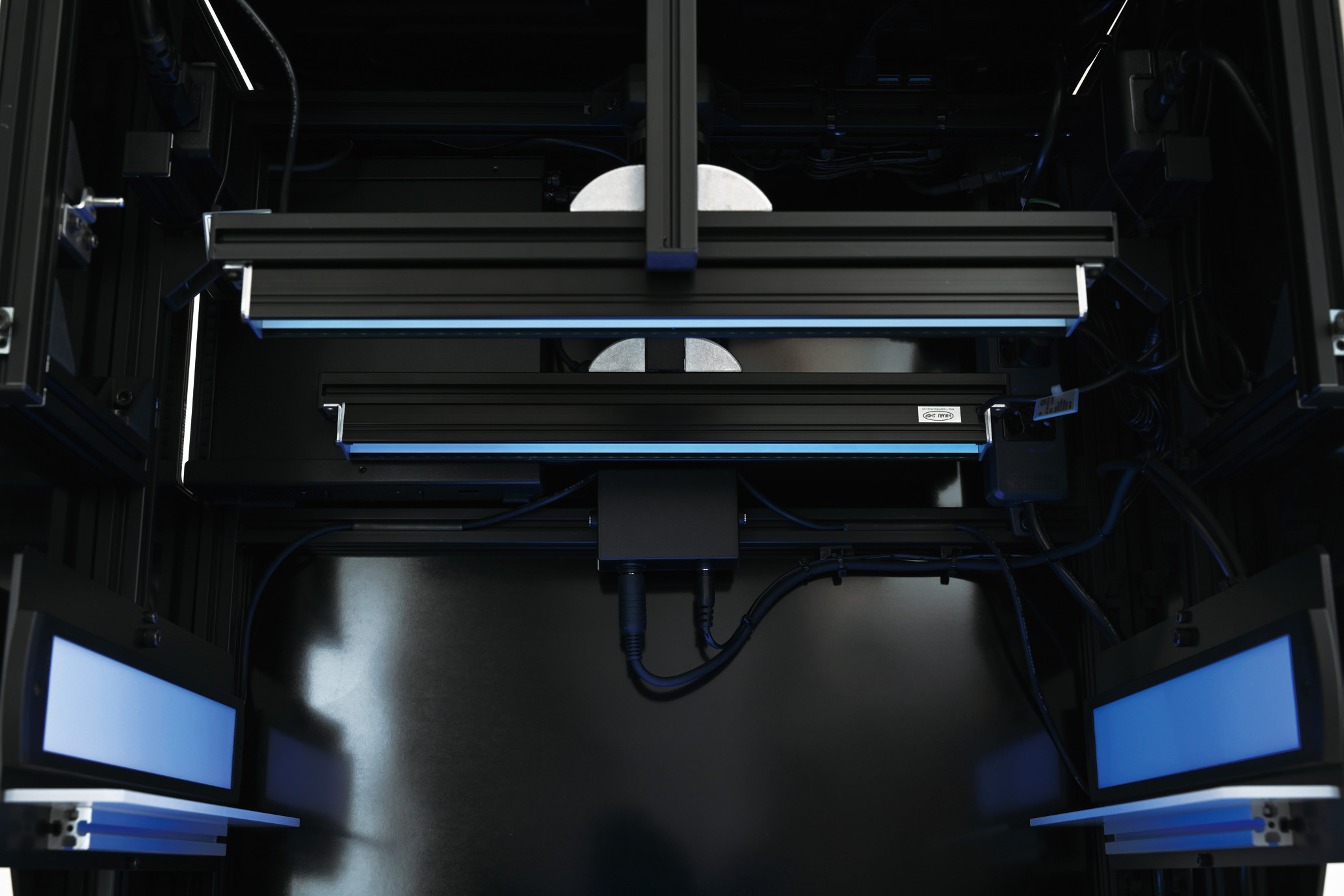

GX2(S/D) 挿入部品検査に最適な2方向フラット照明搭載モデル

左右方向の白色フラットLED照明で、凸凹を浮き上がらせて欠陥を見つけやすくします。部品の有無や極性検査の他、マスキングテープやラベル、ハーネスの色検査にも適合します。

GV2(S/D) 防湿コーティング検査に対応したブラックライト搭載モデル

365nm波長のUV-LED照明2基に加えて白色LEDも搭載することで、UVだけでは難しい基板の位置ズレ補正も問題なし。最小0.3mmの塗りモレ、飛散を検出可能です。白色LEDで部品検査も同時に行えます。

GH2(S/D) はんだ面検査に適した4方向フラット照明搭載モデル

4方向照明で影の影響をなくし、左右と前後の照明画像を演算することも可能。はんだショートや未はんだ(赤目)の検出に最適化しました。背の高い部品が作る谷間部分も明るく照らし、挿入部品の検査も得意です

筐体バリエーション

ST(S/D) 卓上スライドテーブル仕様

基板をスライドテーブルに乗せて検査をするので、完全に密閉されるため検査環境が安定し、繰り返し精度が向上します。電磁ロック機能で検査忘れを防止します。また、上下クリアランス60mmまでオプション対応します。照明は、GV(UV照明)、GH(4方向照明)が選べます。

FL(S/D) フロントローディング仕様

セーフティライトカーテン、非常停止ボタンなど安全機能を搭載表裏両面検査にも対応できます。パレット印字コード読み取りで、自動機種切り替え機能対応装置下部にパレット収納棚があります。写真はL基板対応機です。

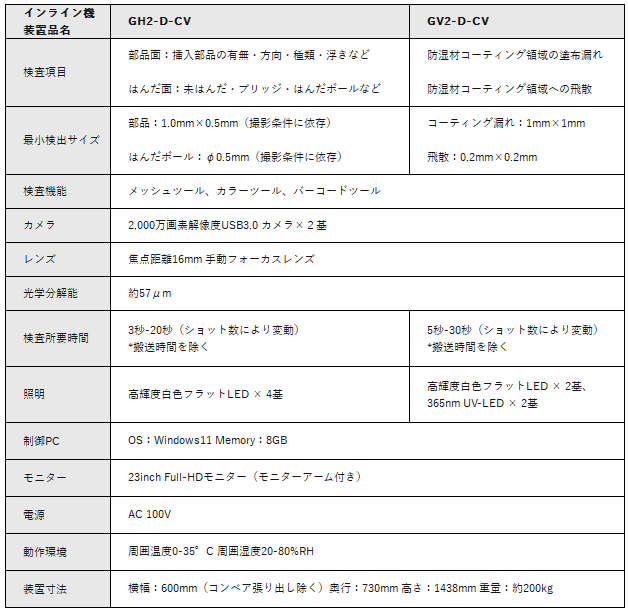

CV(S/D) インライン機仕様

AZVisonをラインに組み込んで、自動化・省人化を行いたいというお客様にこたえて開発しました。ローダー+ストッカーと組み合わせてバッジ検査も可能です。基板印字コード(QR/DM)読み取り機能や、コンベア幅自動調整のオプションなどインライン機としてほしい機能もオプションで対応いたします。

仕様